Transforming Fresh Products into Value-Added Nutritional Products

Fruit and vegetable dehydration is one of the oldest and most effective methods of food preservation, now enhanced by modern technology to meet today’s quality and safety standards. With increasing demand for healthy, long-lasting, and convenient food products, dehydration has become a vital process in the food processing industry. Dehydrated fruits and vegetables are widely used in snacks, ready-to-cook foods, soups, instant meals, bakery products, and health supplements. This blog explains the dehydration process in detail and highlights the many benefits of dehydrated fruits and vegetables.

What Is Dehydration?

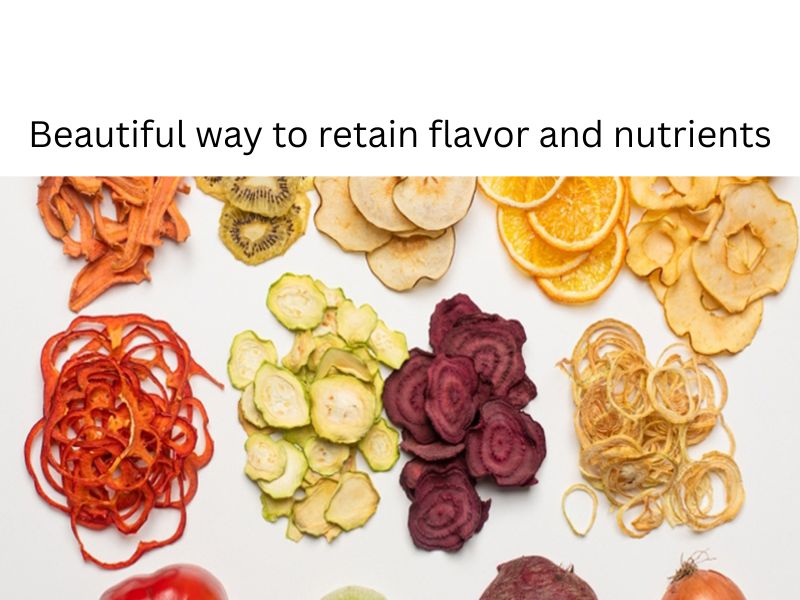

Dehydration is the process of removing moisture from fruits and vegetables under controlled conditions of temperature, airflow, and time. Since microorganisms such as bacteria, yeast, and molds require moisture to grow, reducing water content significantly slows spoilage. Proper dehydration preserves food quality while maintaining nutritional value, taste, color, and texture.

Dehydration Process of Fruits and Vegetables

The dehydration process involves several critical steps to ensure consistent quality and safety:

1. Selection of Raw Material

High-quality, fresh, ripe fruits and vegetables are selected for dehydration. Produce should be free from damage, decay, or contamination. Quality at this stage directly affects the final dehydrated product.

2. Washing and Cleaning

The raw materials are thoroughly washed to remove dirt, pesticides, and microorganisms. In industrial settings, this is done using food-grade washing systems with clean water.

3. Sorting and Grading

Fruits and vegetables are sorted based on size, ripeness, and quality. Uniform pieces ensure even dehydration and better product appearance.

4. Peeling and Cutting

Depending on the product, peeling may be required. The produce is then sliced, diced, or chopped into uniform sizes to ensure consistent drying. Thickness plays a crucial role in drying time and final texture.

5. Blanching (Optional but Important)

Many vegetables undergo blanching before dehydration. Blanching involves briefly exposing produce to hot water or steam, followed by rapid cooling. This step:

- Inactivates enzymes that cause color and flavor loss

- Reduces microbial load

- Improves shelf life

Fruits may also be treated with natural anti-browning agents like lemon juice or ascorbic acid.

6. Dehydration / Drying

This is the core stage of the process. Fruits and vegetables are placed in dehydration units where controlled heat and airflow remove moisture gradually. Common dehydration methods include:

- Hot air drying

- Tray drying

- Tunnel drying

- Vacuum drying

- Freeze drying (for premium products)

Temperature is carefully controlled to avoid nutrient loss, scorching, or case hardening. Moisture is typically reduced to 5–10%, depending on the product.

7. Cooling and Conditioning

After drying, the product is cooled to room temperature to prevent condensation inside packaging. Conditioning ensures uniform moisture distribution across all pieces.

8. Packaging and Storage

Dehydrated products are packed in moisture-proof, food-grade packaging such as laminated pouches or airtight containers. Proper packaging protects against humidity, light, and oxygen, extending shelf life.

Benefits of Fruit and Vegetable Dehydration

1. Extended Shelf Life

One of the biggest advantages of dehydration is significantly longer shelf life. Dehydrated fruits and vegetables can last from several months to over a year when stored properly, without refrigeration.

2. Nutrient Retention

When dehydration is done correctly, most vitamins, minerals, and antioxidants are retained. Fiber, iron, potassium, and plant compounds remain largely intact, making dehydrated produce nutritionally valuable.

3. Reduced Food Waste

Dehydration helps utilize surplus and seasonal produce that would otherwise spoil. This is especially beneficial for farmers and food processors, reducing post-harvest losses.

4. Lightweight and Easy Storage

Removing moisture drastically reduces weight and volume. Dehydrated foods are easy to store, transport, and handle, making them ideal for bulk supply, exports, and emergency food storage.

5. No Chemical Preservatives

Dehydration naturally preserves food without the need for artificial preservatives. This makes dehydrated fruits and vegetables appealing to health-conscious consumers.

6. Convenience and Versatility

Dehydrated produce is easy to use. It can be rehydrated for cooking or consumed directly as snacks. It is widely used in:

- Instant soups and noodles

- Ready-to-eat meals

- Breakfast cereals and granola

- Bakery and confectionery products

- Herbal and health foods

7. Cost-Effective

Lower transportation, storage, and refrigeration costs make dehydration an economical preservation method. It also provides better returns for processors due to reduced spoilage and higher value addition.

8. Year-Round Availability

Seasonal fruits and vegetables can be made available throughout the year in dehydrated form, ensuring consistent supply for consumers and industries.

9. Improved Food Safety

Low moisture levels inhibit microbial growth, reducing the risk of spoilage and foodborne illness when proper hygiene and processing standards are followed.

10. Sustainable and Eco-Friendly

Dehydration supports sustainable food systems by reducing waste, minimizing cold storage dependency, and optimizing resource use. It also supports rural employment and agro-processing industries.