The Future of Natural Food Preservation in India

In today’s fast-developing world, consumers and industries are searching for natural food preservation methods that retain nutrition, extend shelf life, and reduce waste. One such time tested and globally used solution is the food dehydration process. From households to large-scale industries, fruit and vegetable dehydration have become a cornerstone of modern dehydration technology in food processing.

India, with its vast agricultural base, is witnessing strong growth in industrial food dehydration, especially in regions like Maharashtra and Nashik, which are known for high-quality products / raw materials.

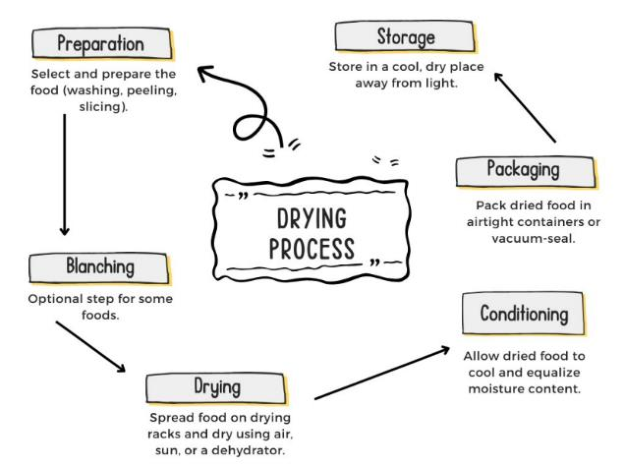

What Is the Food Dehydration Process?

The food dehydration process involves removing moisture from food products under controlled conditions of temperature, airflow, and time. By reducing water content, dehydration prevents the growth of bacteria, yeast, and mold that cause spoilage.

The basic steps include:

-

- Raw material selection – fresh fruits and vegetables are chosen

-

- Cleaning and sorting

-

- Cutting or slicing

-

- Pre-treatment (blanching or sulphiting, if required)

-

- Dehydration using hot air or hot dry air (from which moisture is removed with help of refrigeration cycle)

-

- Cooling

-

- Packaging and storage

This process helps retain flavour, color, and nutritional value while significantly increasing shelf life.

Fruit and Vegetable Dehydration: From Farm to Finished Product

Fruit and vegetable dehydration is one of the most popular segments of food processing in India. Seasonal surplus produce can be converted into value-added products and used year-round.

Commonly Dehydrated Fruits

-

- Banana

-

- Apple

-

- Mango

-

- Papaya

-

- Pomegranate

-

- Amla

Commonly Dehydrated Vegetables

-

- Onion

-

- Garlic

-

- Tomato

-

- Carrot

-

- Beetroot

-

- Green leafy vegetables

Basic Steps Involved

-

- Selection & grading of fresh produce

-

- Washing and cleaning

-

- Peeling, slicing, or chopping

-

- Pre-treatments (blanching or natural dipping)

-

- Controlled dehydration

-

- Cooling and hygienic packaging

Dehydration Technology in Food Processing

Modern dehydration technology in food processing has advanced significantly, ensuring uniform drying, energy efficiency, and food safety.

Popular Dehydration Technologies

-

- Hot air tray dryers / Hot dry air tray dryers

-

- Tunnel dryers

-

- Conveyor belt dryers

-

- Solar dryers

-

- Vacuum dehydration systems

Each technology serves different scales of production, from small entrepreneurs to large industrial food dehydration units.

Industrial Food Dehydration: Growing Demand in India

The demand for industrial food dehydration is rising due to:

-

- Increasing exports of dehydrated vegetables

-

- Growth of ready-to-eat and instant food markets

-

- Rising awareness of healthy, preservative-free foods

India has emerged as a key supplier of dehydrated onion, garlic, and vegetable flakes to global markets.

Dehydration Plant in India: Why Location Matters

Setting up a dehydration plant in India requires strategic planning, especially location selection. States like Maharashtra offer significant advantages.

Why Maharashtra Is Ideal

-

- Abundant agricultural raw material

-

- Strong logistics and road connectivity

-

- Skilled labor availability

-

- Supportive government policies

-

- Proximity to ports for exports

Dehydration Business in Maharashtra: A Profitable Opportunity

The dehydration business in Maharashtra is witnessing rapid growth due to its diverse crop production and entrepreneurial ecosystem.

Benefits of Starting in Maharashtra

-

- Year-round supply of fruits and vegetables

-

- Lower raw material procurement costs

-

- Growing demand from food manufacturers

-

- Access to dehydration unit manufacturers

Dehydration Business in Nashik: The Emerging Hub

Nashik is fast becoming a preferred destination for food processing industries. Known as the “fruit bowl of Maharashtra,” Nashik offers unmatched advantages for dehydration entrepreneurs.

Why Nashik Stands Out

-

- High-quality grapes, onions, tomatoes, and vegetables

-

- Excellent climate for dehydration

-

- Well-developed agro-industrial infrastructure

-

- Growing cluster of dehydration plants

-

- Easy access to dehydration unit manufacturers

The dehydration business in Nashik is especially attractive for startups and MSMEs focusing on quality and export-oriented products.

Role of Dehydration Unit Manufacturers

Choosing reliable dehydration unit manufacturers is critical for business success.

What to Look For

-

- Energy-efficient designs

-

- Uniform drying capability

-

- Food-grade stainless steel construction

-

- Customization options

-

- Strong after-sales support

Modern dehydration units ensure consistent quality and help maintain nutritional value in dehydrated foods.

Dehydrated Food Benefits: Why Consumers Prefer It

The popularity of dehydrated foods is driven by numerous dehydrated food benefits.

Major Benefits

-

- Long dehydrated food shelf life

-

- No artificial preservatives

-

- Lightweight and easy to store

-

- Retains most nutrients

-

- Reduces food waste

-

- Increases calorific density due to reduction of weight

-

- Convenient for cooking and travel

Dehydrated foods are widely used in homes, hotels, food service industries, and packaged food manufacturing.

Dehydrated Food Shelf Life Explained

One of the biggest advantages of dehydration is shelf stability.

Typical Shelf Life

-

- Dehydrated vegetables: 6–12 months

-

- Dehydrated fruits: 6–10 months

-

- Garlic and onion flakes: up to 18 months

Proper packaging and storage conditions play a key role in extending sh

Amongst all Food Preservation Methods, Dehydration Leads the Way

Dehydration stands out as:

-

- Chemical-free

-

- Cost-effective

-

- Environmentally friendly

-

- Suitable for bulk processing

Unlike canning or freezing, dehydration does not require continuous energy input during storage.

Dehydration vs Freezing Food: A Practical Comparison

When comparing dehydration vs freezing food, both have advantages, but dehydration offers clear benefits for commercial use.

| Dehydration | Freezing |

| No refrigeration needed | Requires cold storage |

| Lower energy cost | High energy consumption |

| Longer shelf life at room temp | Limited shelf life |

| Lightweight & easy transport | Heavy & costly logistics |

Conclusion: Dehydration Is the Future of Food Processing

The food dehydration process has transformed how fruits and vegetables are preserved, stored, and consumed. With advancements in dehydration technology in food processing, growing consumer awareness, and strong agricultural support, India is well-positioned as a global leader in dehydrated foods.

Regions like Maharashtra and Nashik offer exceptional opportunities for entrepreneurs looking to enter the dehydration sector. With the right technology, reliable dehydration unit manufacturers, and a focus on quality, the dehydration business promises long-term growth, sustainability, and profitability.

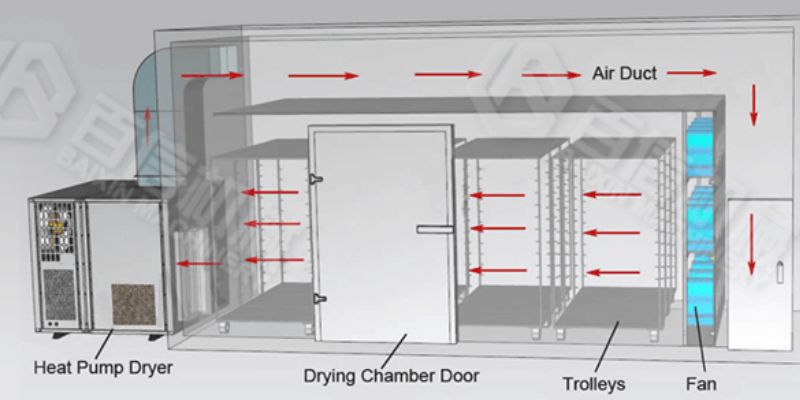

We at Nashik dehydrates use Heat Pump dry air Tray Dehydrater

Block Diagram of Heat Pump Tray Dehydrater

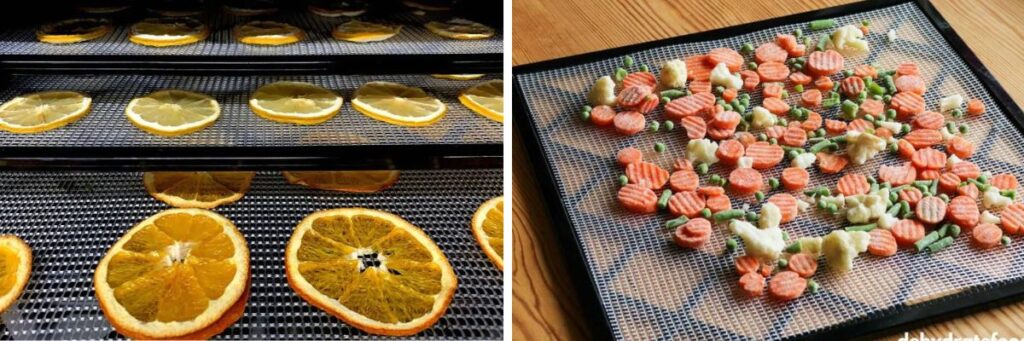

Typical Tray Dehydration

Typical Tray Dehydration

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.