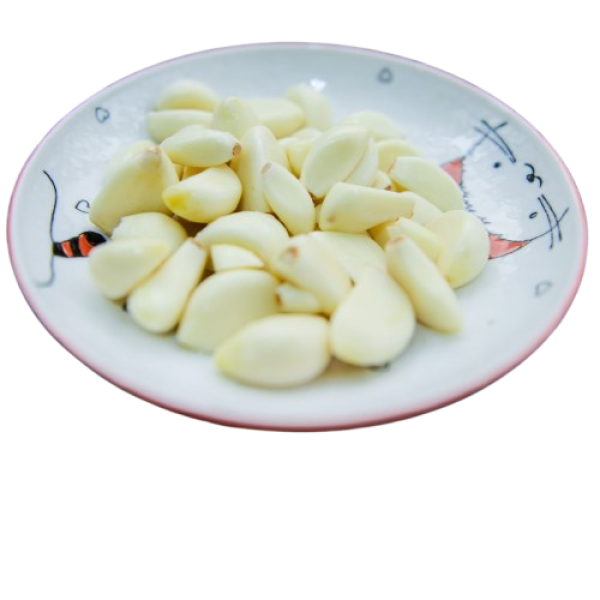

Premium Peeled Garlic – Fresh, Hygienic & Ready to Use

What Is Peeled Garlic?

Peeled garlic is a high‑quality, value‑added food product made from fresh garlic bulbs that are mechanically separated / depoded, peeled, cleaned, and packed under strict hygienic conditions. It offers the full flavor, aroma, and nutritional benefits of fresh garlic. Thus eliminating the need for manual peeling. Peeled garlic is widely preferred by households, hotels, restaurants, catering services, and food processing industries for convenience and consistency.

Key Benefits of Peeled Garlic

Time‑Saving & Convenient: Ready‑to‑use cloves reduce preparation time in kitchens and food factories.

Superior Hygiene: Processed using food‑grade stainless‑steel machines under controlled conditions.

Uniform Quality: Consistent size, color, and freshness in every pack.

High Yield & Low Waste: Minimal clove damage compared to manual peeling.

Versatile Applications: Suitable for cooking, garlic paste, frozen foods, dehydration, and pickling.

Extended Shelf Life: Advanced packing methods help retain freshness and flavor longer.

Peeled Garlic Manufacturing Process

1. Selection of Fresh Garlic

Carefully selected, mature garlic bulbs are sourced from trusted farms and inspected to meet quality standards.

2. Garlic Bulb Breaking

Whole garlic bulbs are efficiently separated into individual cloves using a bulb breaking machine, ensuring minimal breakage.

3. Automatic Garlic Peeling

Cloves are peeled using advanced automatic garlic peeling machines that remove skins gently without the use of water or chemicals, preserving natural quality.

4. Washing & Cleaning

Peeled garlic cloves are thoroughly washed in stainless‑steel washing machines to remove residual skin and impurities.

5. Sorting & Quality Inspection

Cloves are manually or mechanically sorted to remove damaged or undersized pieces, ensuring premium‑grade output.

6. Drying & Moisture Removal

Surface moisture is removed using air dryers or centrifugal dryers, preparing the garlic for safe and long‑lasting packaging.

Machines Used in Peeled Garlic Production

Garlic Bulb Breaking Machine

Designed to separate garlic bulbs into individual cloves quickly and uniformly.

Automatic Garlic Peeling Machine

High‑efficiency machine using compressed air or dry peeling technology to achieve clean peeling with minimal clove damage.

Garlic Washing Machine

Food‑grade stainless‑steel equipment ensuring hygienic and effective cleaning of peeled cloves.

Centrifugal / Air Drying Machine

Removes excess water to enhance shelf life and maintain product quality.

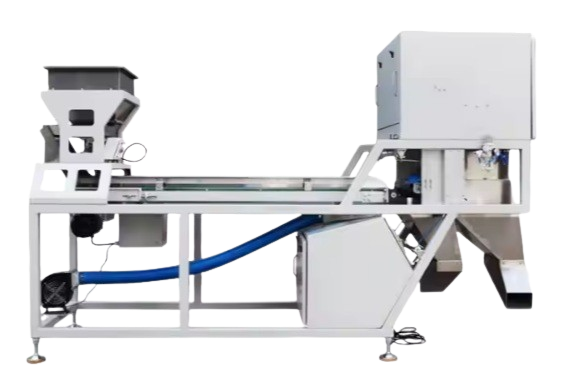

Color Sorting Machine

Removes foreign particles, defective particles and ensures only premium material move to the packing stage.

Removes foreign particles, defective particles and ensures only premium material move to the packing stage.

Grading Machine

Ensures uniform sizing. Thus batches of uniform sizes can be made as per the requirement of customer.

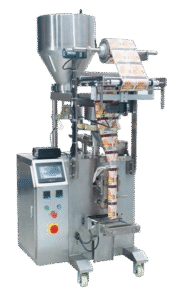

Packing Machine

Automated weighing, filling, and sealing systems for accurate and hygienic packaging.

Packing Options for Peeled Garlic

To meet diverse market needs, peeled garlic is packed using modern, food‑safe packaging solutions:

Vacuum Packaging: Extends shelf life by reducing oxygen exposure. But this machine is applicable for dry material only. Wet material produces vapour and gases. Some times the vapours and gases are produced to such an extent that pouch bulges due to inside gas pressure. Hence the purpose of vacuum packing is not solved.

Modified Atmosphere Packaging (MAP): Maintains freshness, colour, and texture. Air vents are provided on such pouches so that vapour/ gases can be escaped to atmosphere and product remains naturally respirated. (Retail Pouches & Containers: Ideal for supermarkets and home use.) (Bulk Packaging: Suitable for hotels, restaurants, and food processing units).

Cold storage is recommended after packing to preserve freshness, nutritional value, and taste.

Applications of Peeled Garlic

Hotels, restaurants, and catering services

Food processing and manufacturing units

Ready‑to‑cook and frozen food industries

Retail and wholesale markets

Export and bulk buyers

Why Choose Our Peeled Garlic?

Our peeled garlic is produced using advanced machinery, strict quality control, and hygienic processing standards. The result is a fresh, clean, and consistent product that meets domestic and international food safety requirements.

Peeled garlic is the smart, efficient, and profitable solution for modern kitchens and food businesses.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.